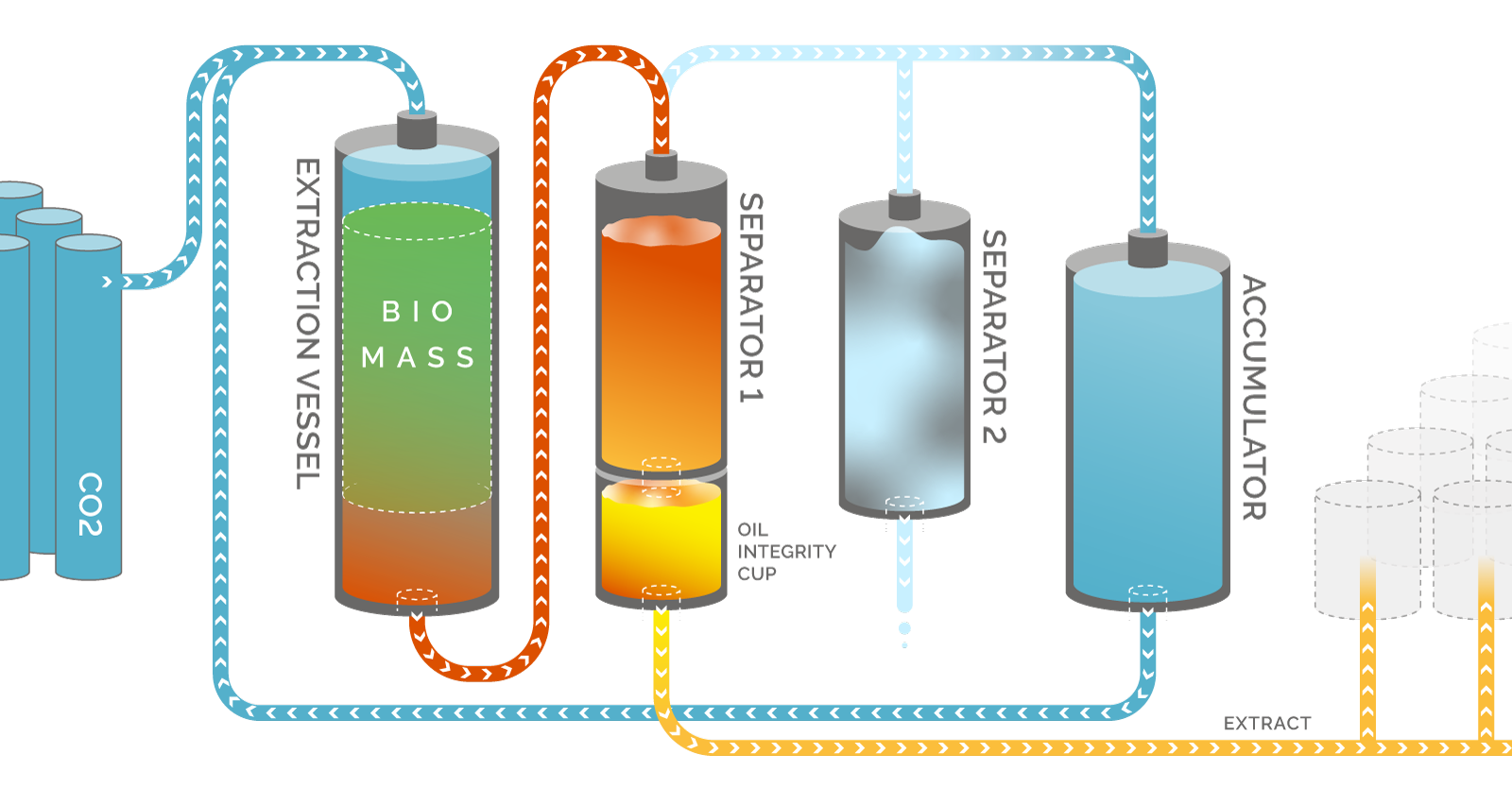

CO2 Extraction Process Diagram

Fill Biomass

Load Extraction Vessel with biomass.Pressurize with CO2

Bring each vessel to working pressure using CO2 from supply cylinders.Run in Closed Loop

In Extraction Vessel, compounds are pulled from biomass into solution.

Solvent (CO2) is boiled out of solution in Separator 1.

Evaporated CO2 is condensed into liquid and stored in Accumulator.

Periodically Sample Extract

Open valve on the Oil Integrity Cup to collect extraction samples. No need to remove the Integrity Cup.Depressurize

After allotted run time, system is depressurized by releasing CO2 through Separator 2.Collect Extract

Extract collected from the Oil Integrity Cup.- 1 – Fill Biomass

Load Extraction Vessel with biomass.

→ - 2 – Pressurize with CO2

Bring each vessel to working pressure using CO2 from supply cylinders.

→ - 3 – Run in Closed Loop

In Extraction Vessel, compounds are pulled from biomass into solution.

Solvent (CO2) is boiled out of solution in Separator 1.

Evaporated CO2 is condensed into liquid and stored in Accumulator.→ - 4 – Periodically Sample Extract

Open valve on the Oil Integrity Cup to collect extraction samples. No need to remove the Integrity Cup.

→ - 5 – Depressurize

After allotted run time, system is depressurized by releasing CO2 through Separator 2.

→ - 6 – Collect Extract

Extract collected from the Oil Integrity Cup.

→