CO2 Extraction

Efficient. Clean. Safe. Versatile.

Discover why CO2 Extraction is the superior method for botanical extraction.

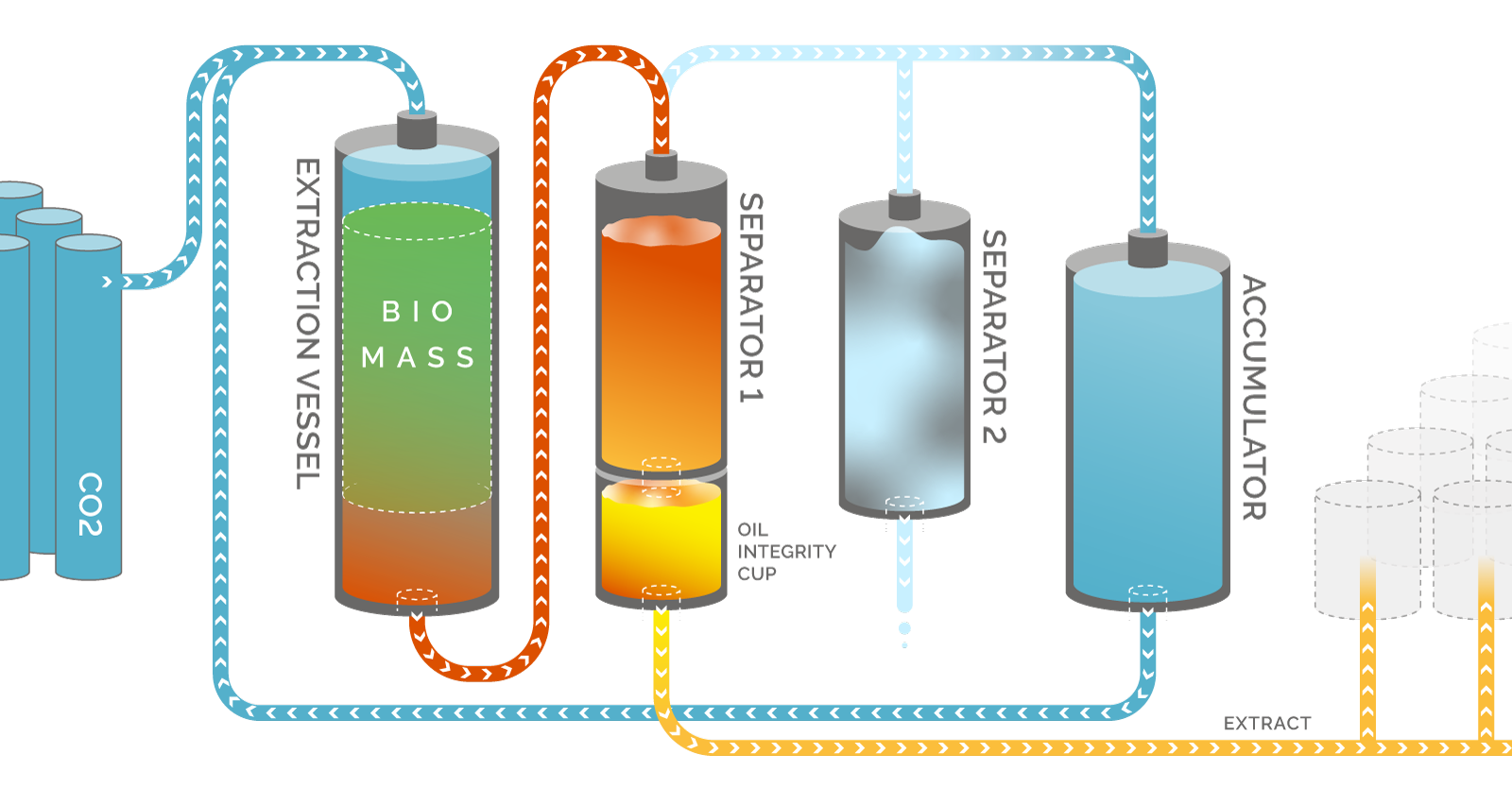

About the CO2 Extraction Process

Fill Biomass

Load Extraction Vessel with biomass.Pressurize with CO2

Bring each vessel to working pressure using CO2 from supply cylinders.Run in Closed Loop

In Extraction Vessel, compounds are pulled from biomass into solution.

Solvent (CO2) is boiled out of solution in Separator 1.

Evaporated CO2 is condensed into liquid and stored in Accumulator.

Periodically Sample Extract

Open valve on the Oil Integrity Cup to collect extraction samples. No need to remove the Integrity Cup.Depressurize

After allotted run time, system is depressurized by releasing CO2 through Separator 2.Collect Extract

Extract collected from the Oil Integrity Cup.- 1 – Fill Biomass

Load Extraction Vessel with biomass.

→ - 2 – Pressurize with CO2

Bring each vessel to working pressure using CO2 from supply cylinders.

→ - 3 – Run in Closed Loop

In Extraction Vessel, compounds are pulled from biomass into solution.

Solvent (CO2) is boiled out of solution in Separator 1.

Evaporated CO2 is condensed into liquid and stored in Accumulator.→ - 4 – Periodically Sample Extract

Open valve on the Oil Integrity Cup to collect extraction samples. No need to remove the Integrity Cup.

→ - 5 – Depressurize

After allotted run time, system is depressurized by releasing CO2 through Separator 2.

→ - 6 – Collect Extract

Extract collected from the Oil Integrity Cup.

→

What is CO2 Extraction?

The Supercritical CO2 extraction process creates phase changes in carbon dioxide utilizing temperature and pressure. CO2 is known as a “tunable solvent” making it extremely versatile for creating a multitude of end products by controlling temperature and pressure. These phase changes create an environment to drop out differing weights of components in the plant material.

The unique design of the Hi-Flo™ Series systems allow for separation and collection of these constituents during a single extraction. This enables collection of light essential oils separately from other desirable constituents and heavier lipids. Supercritical CO2 fluid extraction (SCFE) methodology delivers a clean, unaltered, consistent-yet-flexible product.

CO2: Clean, Safe, Quick

CO2 Extraction is good business. It allows you to create a pure, clean, quality oil that is safe to produce with little-to-no post-processing. Processes that use toxic solvents may require many hours to purge the solvent trapped in the oil. Multiple industries have proven that the highest efficiencies in commercial processing utilize CO2.

CO2 offers you the ability to “tune” the extraction process, especially with a system that will separate constituents during an extraction. You can target specific compounds, like terpenes (terpenoids) and THC/CBD (cannabinoids) through different operational parameters. CO2 is also a sanitizing agent, prolonging shelf life, and, with the proper system and environment, yields food and medical grade oils.

CO2 extraction is a safe, clean, and highly-versatile method of extracting plant botanicals, nutraceuticals, hops, kava kava, essential oils and more.

Efficiency = Profitability

Minimal extraction times, higher yields, low maintenance and low energy consumption enhance profits.

Purity & Safety

We breathe out CO2 with every breath! Evaporated CO2 from the SFE-CO2 process leaves you with virtually no residual solvent. Low temperatures retain ideal organic states.

Versatility Increases Your Options

Use CO2 Extraction methods to pinpoint desired components to be extracted. A solvent that is “tunable” in a system optimizes oil quality, speed and product development opportunities.

Supercritical CO2 Extraction

One of the most amazing things about extracting with CO2 is the ability to separate individual compounds as the extraction is taking place.

This requires a system that will allow for stable temperature and pressure changes during a single run. Because of the stability and flexibility of Eden’s Hi-Flo system, a crude fractionation can be accomplished with the Hi-Flo standard systems. For purer separation, the Hi-Flo FX2 with fractionation is the perfect tool. Fractionation is accomplished in this system by having a series of extract separators in line. As the extract laden CO2 exits the extractor vessel it cascades through these separators. The first separator is set at the highest pressure in the series. The 2nd and 3rd separators ramp downwards in pressure. Different molecular weight compounds drop out at different temperatures and pressures, thus allowing for the fractionation to take place in individual separators. In a standard fractionation scenario, waxes are dropped out in the first separator, heavy oils and resins in the 2nd separator and light oils in the 3rd. Eden Labs has also developed some proprietary fractionation methods for isolating desired compounds in unique ways.

Pioneering Supercritical CO2 Systems

Eden Labs has been engineering Supercritical Fluid Extraction (SFE- CO2) since 1995 and Ethanol distillers since 1994. It began with our vision to promote safer, healthier extraction systems and extracted products for human consumption across industries. This vision has led more than one industry to embrace ethanol and CO2 extraction as non-toxic alternatives in concentration and extraction technology.

Eden Labs offers you options for your innovation. We provide systems for nearly every type of solvent and will work closely with you to find which process is optimal for your product line, your brand and your industry.

We take Our Industry Responsibility Passionately.

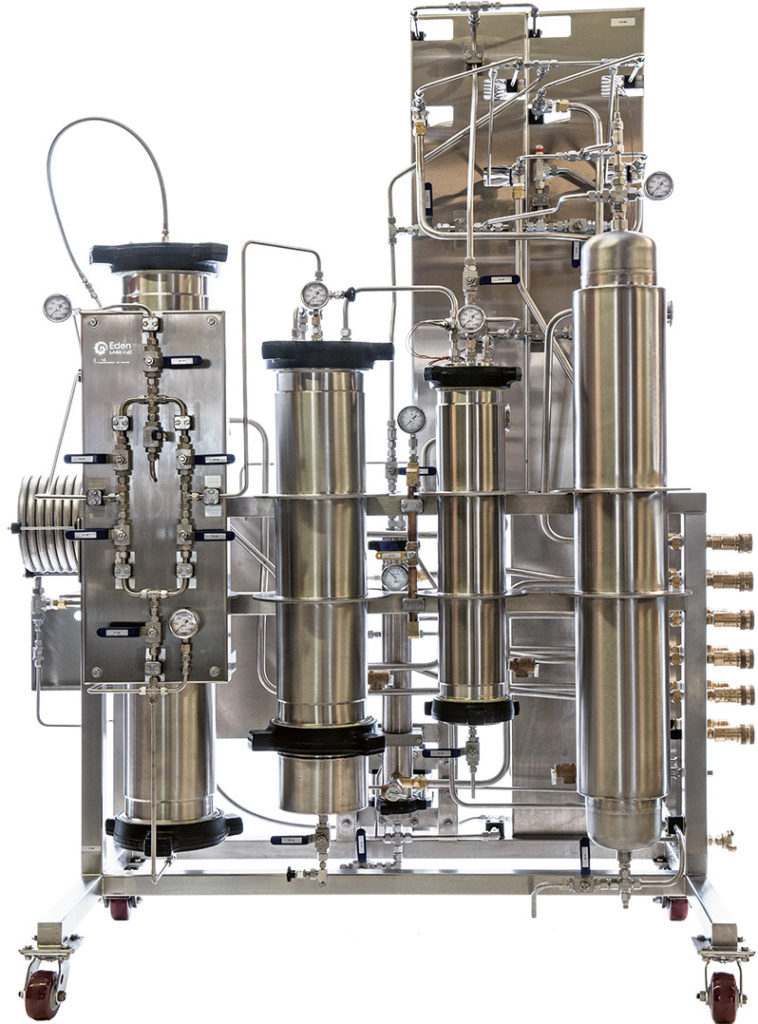

Why Choose Hi-Flo™?

The combination of extensive extraction experience and sophisticated mechanical technology led to the development of the Hi-Flo™ CO2 Extraction System. Our precision manufacturing and continuous R&D has kept the bar high throughout our industry. The Eden system is the benchmark all other systems aim at.

The Hi-Flo™ FX2 delivers the industry’s shortest extraction time with a wider range of use, highest yields, energy efficiency and overall cost effectiveness. The Hi-Flo™ is optimized to take advantage of the tunability of CO2 like no other system. Our custom-tailored solutions provide our customers the ability to innovate and an edge over their competition.

We invite you to run the numbers: no other system comes close to the ROI, reliability and customer service that Eden Labs offers. This directly affects your bottom line and the integrity of your brand.

— From Lead Extractors —

As a Washington State toll processor, it is very important that the extraction equipment we use is exceptionally reliable, protects the material, and creates quality product. Eden Labs CO2 systems are the only way to go. It is scalable, which has allowed my business to grow along with my satisfied clients.