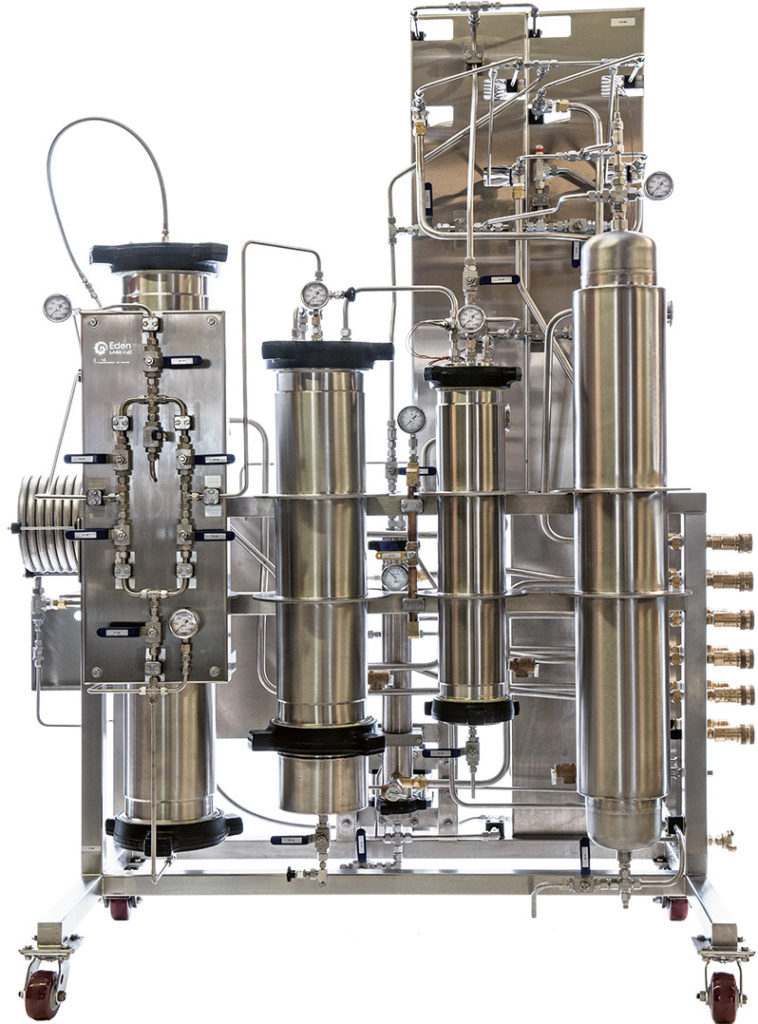

Hi-Flo™ FX2

A Supercritical Fluid Extraction machine re-engineered from the ground up with best-in-class performance capable of processing over 100 lbs. of biomass daily.

The Hi-Flo™ FX2 Series is our lineup of commercial Supercritical extractors capable of processing as much as 107 lbs. biomass daily. With Psi up to 5,000, this series offers best-in-class performance for efficient extraction 24 hours a day, 7 days a week. 1

Talk to Us Quick Sales Inquiry

The system’s sophisticated design yet simple operation gives us fast run-times for heavy resinous oil.

About the Hi-Flo™ FX2

In late 2015, Eden Labs announced the production of the Hi-Flo™ FX2 extraction system, a Supercritical Fluid Extraction machine re-engineered from the ground up.

For the first time the system is offered with both manual and automated extraction systems. This allows industry veterans and newcomers alike to leverage the superior yield and throughput results from Eden Labs’ systems.

What’s New About the FX2?

Significant improvements to the separators, condensers and a maximized pumping mechanism system allow the system to run 500 MLPM to 4 LPM. A monitor provides a full digital readout of the systems operating parameters, data collected, and system performance. The automation software allows data to be collected, stored, and shared for R&D, pilot program rich data analysis, and industrial output evaluation. Learn more by contacting us today.

Features & Benefits

The Hi-Flo™ FX2 High Performance Series has the same reputation for reliability, ease of use, and low-cost maintenance as our Hi-Flo Professional Series. The High Performance Series comes in single 20 Liter and 2 x 20 Liter models. Advanced automation capabilities are available.

With over 20 years of botanical and whole plant extraction expertise, you get fast run times and high yields. Each Eden Labs extractor comes with proven standard operating practices for efficient use and specific products, as well as a three-year warranty.

Non-stop reliability

- Engineered for round-the-clock use

- High quality, durable materials such as 316 stainless steel

- Electric pump for quiet, dependable operations

Simple operations

- Temperature and pressure settings from single console panel

- Fast terpene capture with advanced oil integrity cup design

- Rapid change-over for maximum extraction times

Low maintenance cost

- null

- Closed-loop design with up to 95% CO2 recapture rate

- No internal moving parts so fewer points of failure

- Easy step-by-step protocol for upkeep 2

Our systems comply with US pharmaceutical and nutraceutical requirements. Each is built in accordance with Good Manufacturing Practice (GMP).

| 20 Liter, 2,000 Psi | 20 Liter, 5,000 Psi | 2 x 20 Liter, 2,000 Psi | 2 x 20 Liter, 5,000 Psi 3 | |

|---|---|---|---|---|

| Load capacity (lbs.) 4 | 10 | 10 | 20 | 20 |

| Run time (hrs.) | 7 to 10 | 3 to 7 | 8 to 10 | 4 to 10 |

| Flow rate (liters per minute) | 2.2 | 2.2 | 4 | 4 |

| Floor area (inches) 5 | 68 x 48 x 107 | 106 x 58 x 126 | 252 x 72 x 120 | 252 x 72 x 120 |

| Weight (lbs.) | 2,200 | 2,200 | 2,800 | 2,800 |

The Hi-Flo™ FX2 High Performance Series supports temperature ranges of minus 60 º C to 60 º C. Yields are 12 to 25%, depending on material and extraction parameters. Collection cup design keeps oil cool to preserve integrity.

Which Psi is right you? 2,000 Psi is fine for many botanical and whole plant extractions. Higher Psi like 5,000 gives operators greater tunability and faster run times.

Advanced Automation Capabilities

Developed by a leading global manufacturer, easy-to-read screens give you greater process consistency and replication of desired settings and parameters. 6

List of automation features:

- Timed static fill to optimize cell wall penetration

- Timed terpene fractionation setting

- Timed cannabinoid pulls

- Timed reverse flow to optimize yield

- Stored recipe settings

- Temperature, pressure, and valve settings

- Remote data collection

- Auto shutdown for instant off capability

Hi-Flo FX2 2,000 Psi Models

20 Liter

| Size (in) | Qty. | Weight (lbs) | Phase | Volts | FLA | |

|---|---|---|---|---|---|---|

| Pumping System | Mounted on Unit | 1 | n/a | 1 | 230 | 20 |

| Heating System | 15 x 17 x 17 | 2 | n/a | 3 | 240 | 83 |

| Chiller | 57.1 x 26.6 x 40.7 | 1 | 330 | 3 | 230 | 9.8 |

| Scales | 12 x 12 x 1 1/4 | 3 | 45 | 1 | 110 | 0.5 |

2×20 Liter

| Size (in) | Qty. | Weight (lbs) | Phase | Volts | FLA | |

|---|---|---|---|---|---|---|

| Pumping System | Mounted on Unit | 1 | n/a | 1 | 230 | 20 |

| Heating System | 15 x 17 x 17 | 2 | n/a | 3 | 240 | 83 |

| Water Pump | 6 x 4 x 3-3/16 | 2 | 8 | 1 | 110 | 0.5 |

| Chiller | 57.1 x 31.1 x 45.9 | 1 | 511 | 3 | 230 | 19 |

| Scales | 12 x 12 x 1 1/4 | 3 | 45 | 1 | 110 | 0.5 |

Hi-Flo FX2 5,000 Psi Models

20 Liter

| Size (in) | Qty. | Weight (lbs) | Phase | Volts | FLA | |

|---|---|---|---|---|---|---|

| Pumping System | Mounted on Unit | 1 | n/a | n/a | n/a | n/a |

| Heating System | 15 x 17 x 17 | 2 | n/a | 3 | 240 | 83 |

| Water Pump | 6 x 4 x 3-3/16 | 2 | 8 | 1 | 110 | 0.5 |

| Chiller | 57.1 x 26.6 x 40.7 | 1 | 330 | 3 | 230 | 9.8 |

| Compressor | 76 x 25 x 58 | 1 | 775 | 3 | 208 | 31.6 |

| Scales | 12 x 12 x 1 1/4 | 3 | 45 | 1 | 110 | 0.5 |

2×20 Liter

| Size (in) | Qty. | Weight (lbs) | Phase | Volts | FLA | |

|---|---|---|---|---|---|---|

| Pumping System | Mounted on Unit | 1 | n/a | n/a | n/a | n/a |

| Heating System | 15 x 17 x 17 | 2 | n/a | 3 | 240 | 83 |

| Water Pump | 6 x 4 x 3-3/16 | 2 | 8 | 1 | 230 | 0.5 |

| Chiller | 57.1 x 31.1 x 45.9 | 1 | 511 | 3 | 230 | 19 |

| Compressor | 76 x 25 x 58 | 1 | 775 | 3 | 230 | 31.6 |

| Scales | 12 x 12 x 1 1/4 | 3 | 45 | 1 | 110 | 0.5 |

The 2 x 20 Liter models can be ordered with a single 20 Liter extractor vessel, with the second 20 Liter extractor vessel available as an “in-place” upgrade as your processing volume increases.

Download Product Sheet- Climate controlled environment is recommended.

- 10 – 15 air exchanges per hour, or as required by ventilation regulation.

- Sufficient local ventilation for removal of gases released from system’s vent points.

- Facility electrical supply standards conform with United States National Electrical Code (NEC) standards and supply power at a frequency of 60 hertz.

- Eden Labs’ onsite installation and training is available; operators are fully certified in 2 days. Eden Labs’ Seattle-based training is standard.

- kWh per day consumption in an 8-hour shift ranges from 109.71 to 148.35 depending on model.

Avoid unplanned downtime with a Self-Sufficiency Kit to keep your system operating at peak performance. Each kit contains consumables and spare parts like pressure relief valves, ball valves, filters, pressure gauges, air filters, and metering needle valves.

Bi-annual and annual maintenance plans are available upon request.

Eden Labs recommends on-site installation and training so your operations get up and running fast.

1 Custom industrial systems are available if daily processing needs are larger.

2 When applying Eden Labs Standard Operating Practices.

3 Eden Labs can build custom industrial, higher capacity systems like 2 x 100 Liter, 3 x 500 Liter, and 3 x 2000 Liter.

4 Actual load capacity will vary with density of plant material.

5 Floor area coverage includes chiller.

6 Automation is available on 5,000 Psi models only.